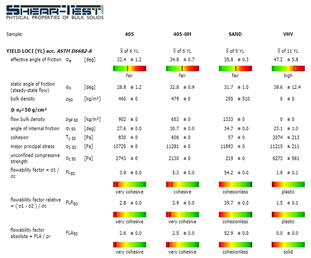

DENSITY OF BULK MATERIALS

DIN ISO 697

The bulk density (ρb0, ρSch) is the ratio of weight to total volume including the voids and pores of the bulk material in the unconsolidated state. It is given in [kg/m³] or in [g/cm³].

TAP DENSITY (ρbK)

DIN EN ISO 787-11, ASTM B527

The tamped density is defined as the density of a bulk material after compaction by shaking, tamping or knocking.

Depending on the standard, different methods are used to determine the tapped density. A certain volume or mass of a random sample is placed in a measuring cylinder with as little vibration as possible. The resulting initial weight or the resulting volume is determined. The resulting initial bulk density is determined.

The measuring cylinder with sample is tamped on in the tamping volumeter with a fixed tamping height and number of repetitions. The tamped density is then calculated from the quotient of the weighed-in mass and the resulting tamped volume.

Characteristic values can be calculated from the data obtained.

The Hausner ratio is a dimensionless physical index which describes the ratio of the unconsolidated bulk density volume divided by the tapped volume.

Compressibility Index is defined as the percentage change in volume by tapping a sample of fixed mass.

Kompressibilitätsfaktor

(%) |

Hausner-Faktor |

Fließeigenschaften |

| < 10 |

1.00 - 1.11 |

Hervorragend |

| 11 - 15 |

1.12 - 1.18 |

Gut |

| 16 - 20 |

1.19 - 1.25 |

Mittelmäßig |

| 21 - 25 |

1.26 - 1.34 |

Ausreichend |

| 26 - 31 |

1.35 - 1.45 |

Schlecht |

| 32 - 37 |

1.46 - 1.59 |

Sehr schlecht |

| > 38 |

> 1.60 |

Sehr, sehr schlecht |

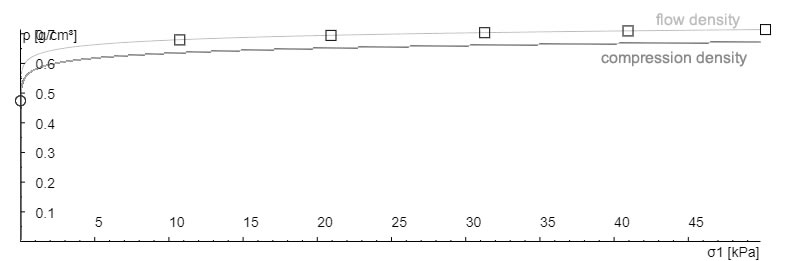

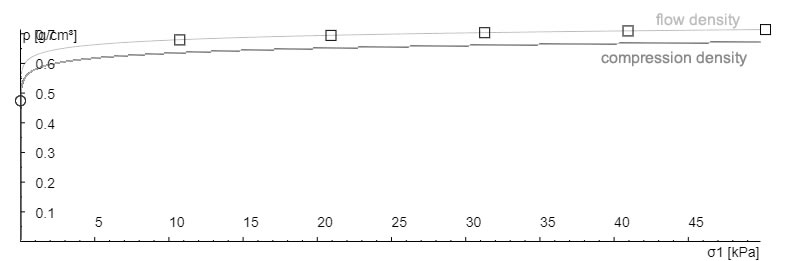

COMPRESSION DENSITY (ρbC)

ASTM-D6682-B

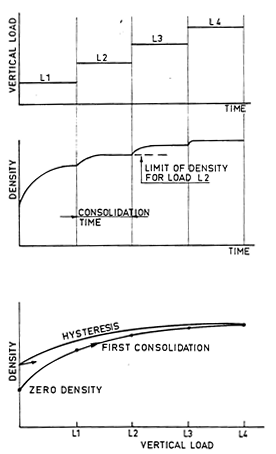

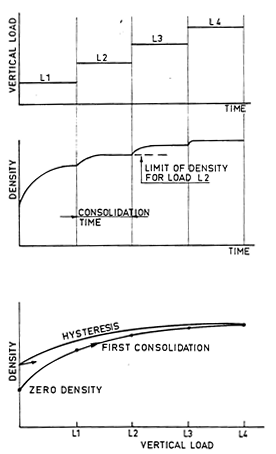

A bulk material is exposed to various external forces. When storing a bulk material in a silo, the pressure the bulk material is exposed to increases with increasing depth. The packing density of the particles also increases (i.e. the density of the bulk material increases).

The change in the packing density of the particles has a great impact on the behaviour of the bulk material. With smaller particle spacing, the contact surfaces between the particles are larger and the forces between the individual particles are increased.

The bulk density (ρb) describes the ratio of the mass (m) of the bulk material to its volume (V). The density of a bulk material at a pressure of zero is called the bulk density (ρb0). With cohesive materials, the resulting bulk density is not completely reversible, and exhibits hysteresis.

When filling a container or when there is mass flow in the shaft and no shear movement has occurred in the bulk material, the material is subject to uniaxial compression. Through shearing a reorientation of the particles to one other is possible, which results in a higher density.

FLOW DENSITY

ASTM-D6682-A

During measurement of the yield locus, the density is measured simultaneously under the influence of pressure and shear stress. Even if the DIN only considers uniaxial compaction, both types of compaction can be used in automatic evaluations.

| SHEAR STRESSES - MEASUREMENT ACCORDING ASTM D6682-A |

| σr |

Τrm |

ρrm |

Τrs |

ρrs |

σN |

Τm |

ρm |

| [Pa] |

[Pa] |

[g/cm³] |

[Pa] |

[g/cm³] |

[Pa] |

[Pa] |

[g/cm³] |

|

| 14871 |

10758 |

1.499 |

9143 |

1.497 |

14871 |

10649 |

1.499 |

| |

|

|

|

|

|

|

|

| ... |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| 14871 |

11132 |

1.501 |

9460 |

1.498 |

3103 |

2596 |

1.498 |

| |

| ρb0 = |

1.286 |

g/cm³ |

bulk density |

| ρbr = |

1.497 |

g/cm³ |

density(σr) = bulk density after consolidation |

Example: Uniaxial compression and flow density of a bulk material