Wall Friction of Bulk Solids

Experimental determination of wall yield locus, analysis of static and dynamic friction and their influence on silo behavior

Fundamentals of Wall Friction

The wall friction of a bulk solid is crucial for pressure and flow behavior in silos. The measurement of the wall yield locus is performed analogously to the determination of internal friction of a bulk solid, where particles are sheared against particles. The essential difference is that the bulk solid is sheared against a defined wall surface.

Wall friction is described by wall friction coefficients that characterize the friction resistance as a function of normal stress. The wall friction coefficient μw is defined as the ratio of wall shear stress τw to the normal stress σ acting on the wall:

The wall yield locus is described by the linear relationship τw = σ · tan(φw) + aw, where φw is the wall friction angle and aw is the wall adhesion. These parameters are required for standard-compliant silo design.

Static and Dynamic Friction

Analogous to static and dynamic friction in solid-state physics, friction measurement between bulk solids and wall surfaces shows a characteristic stress peak (static friction τs) that must be exceeded to set the bulk solid in motion on the surface. The subsequent continuous sliding occurs at dynamic friction τd, which is typically equal or lower.

For silo calculation according to EN 1991-4, dynamic friction is used as it describes the steady state during flow. The lower dynamic friction coefficient leads to higher silo pressures since wall friction is assumed to be lower. However, for flow behavior from the static state, static friction is also relevant.

Experimental Determination of Wall Yield Locus

The determination of wall friction parameters is performed through step-by-step loading and shear stress measurement. To determine the dependence of friction resistance on pressure loading, the resulting wall yield locus is measured in steps:

- Sample preparation: Conditioning of bulk solid material and preparation of representative wall sample.

- Normal stress application: Step-by-step application of defined normal stresses σN.

- Friction resistance measurement: Repeated shearing at constant normal stress and determination of static and dynamic friction resistance.*

- Evaluation: Construction of wall yield locus through linear approximation of measurement points.

*In contrast to solid bodies, wall friction in bulk solids is not immediately fully mobilized due to particle rearrangement in the shear plane. Through repeated shearing at constant normal stress, particle reorientation occurs until friction resistance reaches its maximum. This maximum value characterizes the measurement result for the corresponding normal stress.

For measuring the wall yield locus, we prefer a representative sample of your used wall material. Cutting can also be done in our laboratory. For standard materials such as structural steel, stainless steel, various plastics, PTFE or ceramics, we can provide wall samples.

Surface Changes and Time Consolidation

Analogous to time consolidation in internal friction, time-dependent changes can also occur with wall friction. Likewise, the wall surface can change significantly through shear movements of the bulk solid:

- Material deposits: Caking in or on the wall surface leads to increasing friction coefficients

- Surface smoothing: Mechanical polishing can lead to strongly decreasing friction coefficients

- Chemical interactions: Corrosion or chemical reactions between bulk solid and wall material

- Temperature influences: Changes in material properties through temperature fluctuations

- Moisture influences: Condensation and its effect on friction properties

These changes can increase pressure loading in silos by several hundred percent during operation and thus lead to structural failure. Regular monitoring of wall friction properties is therefore essential for operational safety and is recommended in critical cases.

In special tests, we can simulate shear loading on the wall surface over a defined time period and subsequently quantify changes in friction coefficients.

Example of Wall Friction Measurement

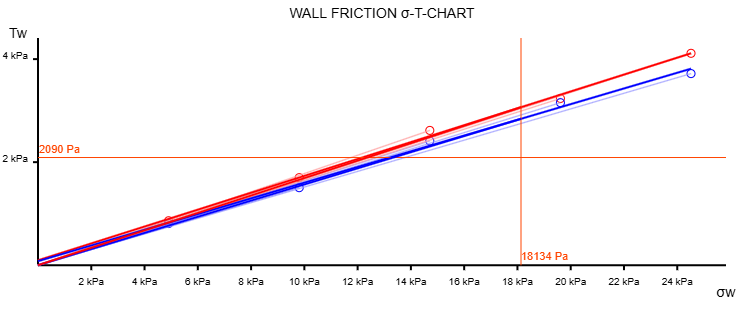

The following representation shows a typical measurement result with the characteristic parameters of the wall yield locus. The analysis includes both static friction and dynamic friction: