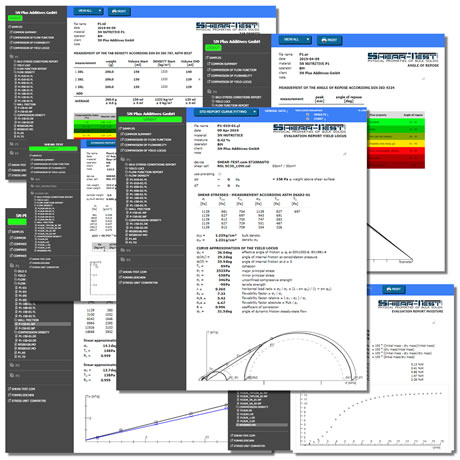

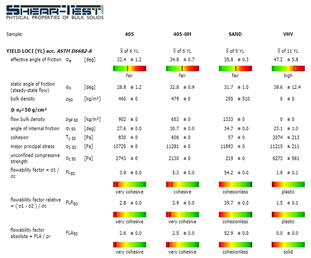

Flowability factor (FL, FLR, FLA, ffc)

Through the measurement of a yield locus, various physical properties can be determined, characterizing individual features of the bulk material. These properties include, the principal stresses (σ1 and σ2), unconfined compressive strength (σc), tensile strength (σt), internal friction angle (φi), cohesion (Τc), and other parameters.

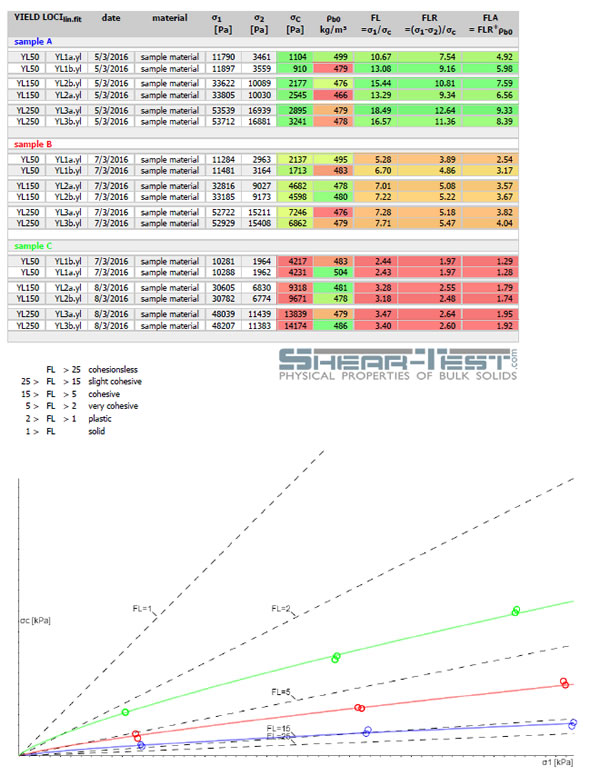

The flowability factor provides a simple and rapid means to quantitatively select materials based on their flowability. To classify powders and quantify flowability into a single parameter, the flowability factor (FL = ffc = σ1/σc) has proven to be the most commonly used. This dimensionless factor facilitates the classification of bulk materials into different categories, corresponding to the ratio of consolidation stress to the compressive strength of a bulk material. When evaluating the numerical values, the exponential increase of the flow factor should be noted.

The categorization of bulk materials based on the flowability factor (FL) is as follows:

| FL | > 25 | cohesionless | |

| 25 > | FL | > 15 | slightly cohesive |

| 15 > | FL | > 5 | cohesive |

| 5 > | FL | > 2 | very cohesive |

| 2 > | FL | > 1 | plastic |

| 1 > | FL | solid |

Further development of this factor may lead to a more precise classification of bulk materials. The relative flow factor (FLR) is calculated as follows: FLR = (σ1 - σ2) / σc.

To make bulk materials with different densities comparable, the absolute flowability factor is often used. This is obtained by multiplying the relative flow factor by the bulk density: FLA = FLR * ρb0

Each measured yield locus and the results always refer to the reference consolidation stress or the largest principal stress (σ1). To compare materials based on the flowability factor, the same consolidation stress must always be assumed. Results based on different initial measurement conditions cannot be compared.

Bulk materials with similar flowability factors should exhibit similar flow behavior in application. Higher values indicate better flow properties, while lower values suggest restricted flowability, necessitating verification of silo flow or processing capabilities.

This method offers a reliable means to ensure the usability of process technology during product transitions or for different batches of raw or finished materials.

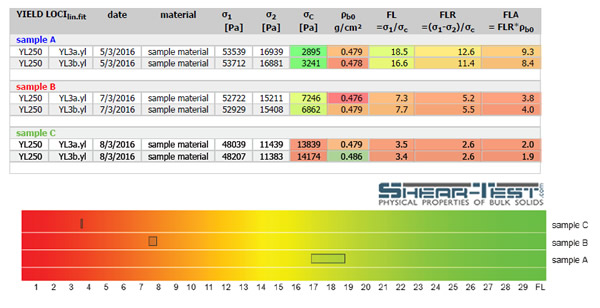

Flow Function

By measuring multiple yield loci at various consolidation stresses, one obtains the flow function, which describes flowability over a range of stresses.

The flow function is used for further technological calculations. To determine it, yield loci are measured at a minimum of three different consolidation stresses covering the application range. Often, the flow function is represented by a linear equation, which simplifies calculations. However, in lower stress ranges, a curved trend is often observed, which is theoretically justifiable. A flowability factor less than one is not possible, as compressive strength (σc) cannot be greater than the largest principal stress (σ1).

At higher stresses, bulk materials may exhibit altered flow properties due to saturation effects, decomposition, or abrasion. Clumping or similar effects can also occur, affecting flowability. By measuring over a wider stress range, these effects can be identified and application safety ensured.

Flow functions with associated flowability factors for three different materials. Automatically generated analysis of the flow function(s) according to the measurements.