Time Consolidation of Bulk Solids

Cohesion increase during prolonged storage - measurement and effects on flowability of bulk solids

Bulk solids can undergo time consolidation when stored in a stationary state (without being sheared). Time consolidation is caused by physical and chemical processes, such as crystallization and sintering processes or chemical solid-state reactions. Technological problems can arise due to increased cohesion, internal/effective friction, and compressive strength.

Fundamentals of Time Consolidation

Time consolidation primarily causes an increase in cohesion Τc. Cohesion refers to the intrinsic shear strength of a material in the absence of normal stresses. During prolonged storage under compressive loading, particle reorientation and the formation of interparticle bonds through chemical or physical processes may occur, leading to an increase in cohesion.

The internal friction angle, however, shows relative constancy, as it is primarily determined by the texture and structural properties of the material, which are usually only slightly influenced by time consolidation. Time consolidation mainly modifies the interparticle adhesive forces that determine cohesion, while particle friction, which defines the internal friction angle, remains largely unchanged.

Experimental Determination of Time Consolidation

- Determination of the direct yield locus without time consolidation.

- Conducting time consolidation tests by applying constant normal stress σN and shear stress τ over defined time intervals (24 h, 48 h, etc.).

- After the consolidation time has elapsed, the critical shear stress Τmax is measured again to quantify the time-dependent strength increase.

- Calculation of the shear stress difference (ΔΤ = ΤTIME - Τdirect) to quantify the cohesive increase through time consolidation. This difference corresponds to the time consolidation factor ΔΤC.

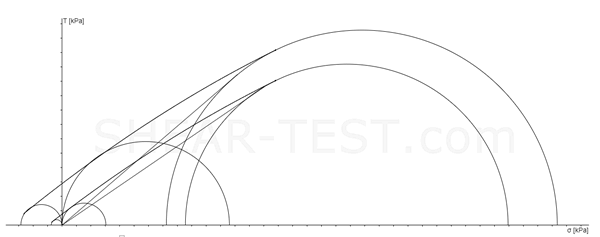

- Construction of the time-dependent yield locus by translation of the direct yield locus by the time consolidation factor ΔΤC. The resulting yield locus shows an increased cohesion Τc with unchanged slope of the internal friction angle φi.

Methodology and Advantages

This methodology represents an established procedure in powder technology for evaluating time-dependent strength changes. It eliminates the need for individual time consolidation measurements for each individual shear point, resulting in significant time and cost savings. The procedure is based on the experimentally validated finding that time consolidation primarily affects cohesion, while the internal friction angle remains nearly constant.

Influencing Factors and Temporal Behavior

The cohesive increase through time consolidation is influenced by multiple parameters, including material characteristics, normal stress level, and loading duration. Time consolidation usually reaches a plateau after a material-specific time period, whereby further cohesive increases are limited or completely inhibited.

In practical applications, time consolidation must be considered for both internal friction and wall friction. The time-dependent changes in adhesion affect not only the flow behavior of the bulk solid, but also the interaction with container walls and conveying elements. This is particularly important in the design of silos, bunker systems, and conveying equipment, as storage and flow behavior can change over time due to caking and increased wall friction.

Comparison: Direct Yield Locus vs. Time Yield Locus

- A Direct Yield Locus (YL) without time consolidation

- Time Yield Locus (YLT) with time consolidation at the same normal stress σN (after 30 minutes, 60 minutes, 6 hours, 12 hours, 24 hours, 48 hours, etc.)

Direct Yield Locus and Time Yield Locus Comparison